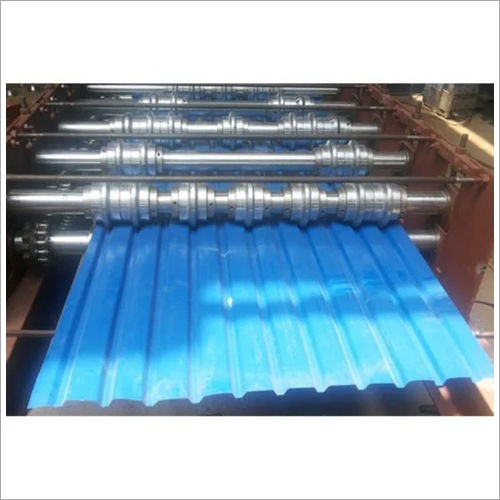

Deck Sheet Roll Forming Machine

Price 3500000.0 INR/ Piece

MOQ : 1 Piece

Deck Sheet Roll Forming Machine Specification

- Type

- Deck Sheet Roll Forming Machine

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Voltage

- 220-440 Volt (v)

- Color

- Blue

- Warranty

- 1 Year

Deck Sheet Roll Forming Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 15-30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Deck Sheet Roll Forming Machine

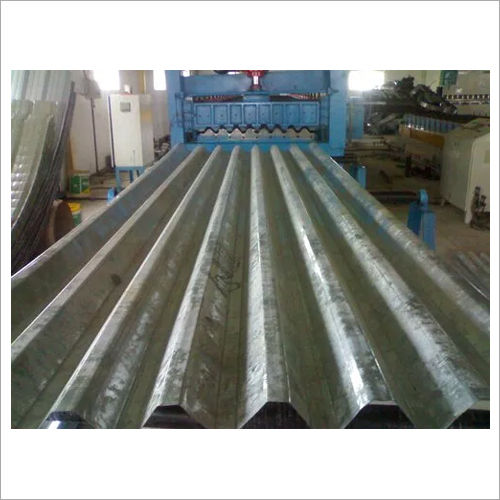

We are creating a brand name in every part of the national market by manufacturing and supplying an exclusive range of Deck Sheet Roll Forming Machine. This machine is used to press and form rolls using metal sheets. At our sophisticated production unit, we manufacture this machine using high-quality cast iron and steel. Clients can obtain our Deck Sheet Roll Forming Machine with different technical specifications from us.

Advanced Semi-Automatic Technology

Experience seamless operation with the semi-automatic Deck Sheet Roll Forming Machine. Its computerized controls enable precise shaping of deck sheets while reducing manual intervention. The machine is designed for durability, ensuring consistent results over extended periods.

Versatile Voltage Compatibility

Compatible with a broad voltage range (220-440V), this machine integrates effortlessly into various industrial settings. Its adaptability supports different power environments, making it a preferred choice for manufacturers nationwide.

FAQs of Deck Sheet Roll Forming Machine:

Q: How does the Deck Sheet Roll Forming Machine improve productivity?

A: By automating key aspects of the deck sheet forming process, the semi-automatic, computerized Deck Sheet Roll Forming Machine streamlines operations, reduces manual labor, and enhances overall output efficiency.Q: What is the warranty coverage for the Deck Sheet Roll Forming Machine?

A: This machine is backed by a one-year warranty, providing assurance against manufacturing defects and offering timely support for repairs or technical concerns.Q: When should I use a deck sheet roll forming machine in my production process?

A: Deploy this machine during the fabrication stage where deck sheets are required for flooring or roofing in construction projects. It ensures uniformity and precision in sheet forming.Q: Where can I source the Deck Sheet Roll Forming Machine?

A: As an exporter, manufacturer, and supplier based in India, we provide nationwide as well as international delivery through a reliable distribution network.Q: What is the operational process for using the machine?

A: After configuring parameters via the computerized control system, the raw material is loaded, and the machine semi-automatically forms deck sheets with precise specifications as programmed.Q: What are the benefits of using this machine in construction manufacturing?

A: Users benefit from increased speed, reduced errors, lower labor costs, and consistent product quality, making it invaluable for projects demanding high standards.Q: How is voltage compatibility ensured for different work environments?

A: The machine operates efficiently within a 220-440V range, enabling it to adapt to various industrial power setups without the need for extensive adjustments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet Roll Forming Machine Manufacturer Category

7 High Ribs Roofing Sheet Roll Forming Machine

Price 1750000 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Material : Metal

Warranty : 1 Year

Color : Blue

Silo Sheet Panel Making Machine

Price 1900000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Material : Metal

Warranty : 1 Year

Color : Silver

Wall Panel Sheet Roll Forming Machine

Price 1100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Material : Metal

Warranty : 1 Year

Color : Silver

Rail Roof Sheet Forming Machine

Price 9500000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Material : Metal

Warranty : 1 Year

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry